We are a Portuguese brand with strong and dynamic DNA in area of concrete floors and coverings. We have one strong connection to technical knowledge, innovative design, quality, performance and strength of our materials and solutions. We have been in the market for over 48 years with reference architecture projects and interior design worldwide. In Portugal we are responsible for the most important road infrastructures, floors and wall tiles of some of the largest public, commercial, educational and sports reference jobs. We have evolved with our commitment with innovation, design, quality, environment and safety of our solutions, products and raw materials. From genesis and collection of raw material to the final process, we follow all the steps until we reach the product that we trade. Thanks to the excellent technical and visual properties, ACL’s indoor and outdoor flooring and coverings are now used in all types of international architectural projects.

Quality and Environment Policy

ACL reaffirms the adoption of the principles of Sustainable Development as an integral part of its business strategy, assuming clear performance commitments, in the areas of Quality and Environment.

- QUALITY

Control the quality of the processes, the raw material and the finished product, in order to reduce costs and losses.

Streamline partnerships with suppliers to make the product and service more profitable.

The company also takes into account that it must move towards following the needs and expectations of the interested parties. - ENVIRONMENT

Identify the environmental aspects and minimize the environmental impacts of the ACL's activities, through the prevention of pollution.

Use the necessary resources in a sustainable manner, by adopting new work practices and available technologies, promoting increased energy efficiency, reducing atmospheric emissions and the consumption of natural resources, such as energy.

Preserve the surrounding environment through the effective control of chemical products and the correct separation and routing of waste. - A Cimenteira do Louro undertakes to comply with all applicable legal requirements and other requirements to which the organization subscribes.

The policy is communicated to all employees, the general public, customers, suppliers, subcontractors and interested parties.

The collaboration and commitment of all are essential in the commitment to continuous improvement of the company, which is defined by the improvement of performance, review and evaluation of the management systems, objectives and goals implemented.

Quality

- The continuous improvement of the quality of our products is an essential goal at Cimenteira do Louro. Continuous assessment of the Quality System is a form of guaranteeing this evolution, considering that each business area will meet the requirements of the Quality Policy. Recent certification in the field of Quality, based on the NP EN ISO 9001 standard, allows for a better adjustment to market requirements.

Environment

We protect the environment!

- For us, environment is not a trend, it’s an objective reality. The assessment and systematic control of the environmental impacts of our activities are priority concerns.

- In 2018, we started implementing 1.984 photovoltaic panels in our factory, thus favoring increased consumption of renewable energy.

- Environmental protection assumes an increasing importance in our society, a reality that A Cimenteira do Louro shares and promotes.

- EN ISO 14001 Standard Certification is proof of that concern and makes our company the first in its sector to obtain that Standard in Portugal.

- Concrete products are composed of cement, sand, aggregates and water, being 100% recyclable.

Our waste is separated and sent to licensed entities for this purpose, with about 99.9% of waste sent for recycling.

The resource consumption is also a concern. The rejected water, in the production process, is treated and reused internally.

Safety

- Implement procedures for identifying hazards, assessing risks and determining control measures in terms of occupational health and safety resulting from the activities of the ACL.

- Promote the reduction, elimination or control of risks associated with the circulation of machines, noise, silica and ergonomic risks, preventing incidents, injuries or injuries, accidents and damage to health or occupational diseases.

- Investing in prevention through training, communication, participation and consultation with workers, so that they are aware of their individual OSH obligations, raising awareness of the increased protection of machinery and work equipment and the importance of using Personal protective equipment.

NP EN ISO 14001

Sustainability

- Since its creation, ACL has sought to evolve in a sustainable way, as we believe that this aspect is essential for the company to remain competitive.

Carbon footprint!

We are already on the way to carbon neutrality.

- So far we have already produced 2141 MWh

- So far we have already saved 1006 ton of CO2 emissions

2022

We continue to create history...

We are determined to offer solutions of unique, functional and innovative products; our secret is to combine technical know-how and innovative design. We are attentive to your needs!

Envolving towards design & innovation

2020

ACL Meeting@Panamá

In 2020, ACL was in Panama, at an event he created for this purpose at the Hotel Eurostars Panama City. The event took place between the 26th and 27th of February 2020, right in the center of Panama City, the capital.

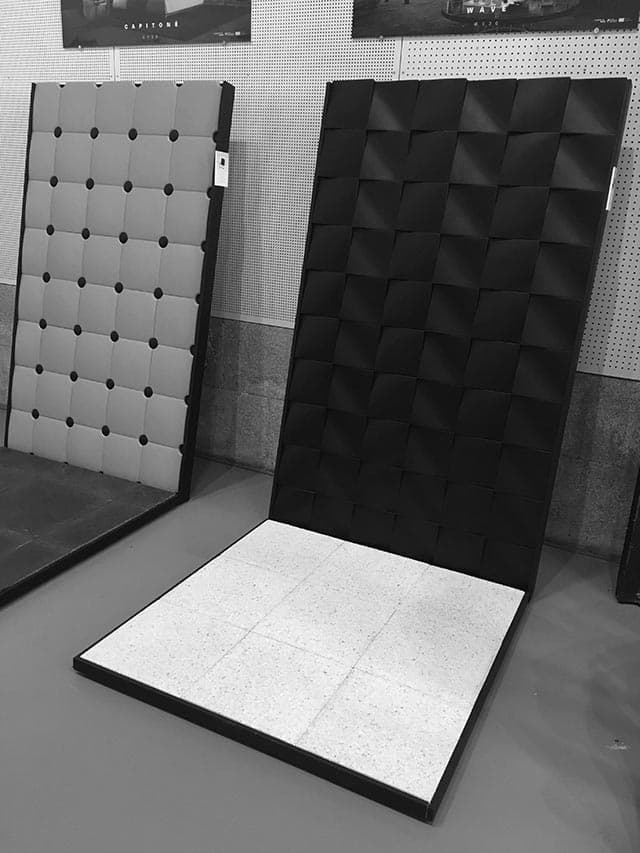

It was a unique opportunity to showcase the uniqueness, quality, design, innovation, art and industry heritage of the wall coverings and concrete flooring.

The products selected and presented were collections from the Design and Natural lines of wall coverings, as well as flooring products.

2019

Logo Refresh

We refresh the ACL logo…

With a new energy, the logo retains all the power and Design that defines the ACL brand.

Participation in new International Exhibitions

In 2019, ACL participated for the first time in several Architect @ work (Paris, Turin, Munich, Milan, Dusseldorf) and Downtown Design (Dubai).

Participation in these fairs has become an opportunity to showcase the Uniqueness, Quality, Design, Innovation, Art and Heritage of the Concrete Flooring and wall tiles Industry.

2018

Certificate - PME Lider 2018

ACL was distinguished by IAPMEI, for its business strategy and important contribution to the national economy.

Metro station Panama

First metro station in Panama, it's expected that the line will be completed by 2019.

The works are in progress, as is the laying of the concrete flooring MARMOCIM.

2017

ACL – São João Experience

This initiative brings together partners and customers for a visit to the ACL factory, among other activities.

Formula E - New York City ePrix Circuit

ACL marked its presence in another race driven by electric cars. This time the Formula E race took place in one of the world's most iconic cities, New York.

2016

Launch of the ECOBLOCO Masonry Line

ECOBLOCO is a line of masonry products that, through its technical features, allows the final user to save.

Formula E Berlin E-PRIX Circuit

ACL/4CT partnership, in the Assembly/Disassembly Circuit Formula E ePrix Berlin - 21 May 2016.

2013

Pavilion 7

Expansion of the manufacturing area for the production of technical floorings, raised access floorings and self supporting floorings.

2008 - 2013

School park

The Marmocim flooring was part of the remodeling of the National Schools.

Highway

Curb stone beams, highway New Jersey barriers (k-rail) and concrete panels were some of the materials that helped build Portuguese highways (A1, A3, A4, A6, A7, A10, A11, A13, A23, A25, A28).

2007

Pavilion 6

Coatings

ACL launches a line of concrete coatings, versatile and innovative, adaptive to the various divisions and add comfort to the environment of your home. In our company your well-being is always present in the development of our products.

2006

Criação dois laboratórios

With application of the CE marking on our products a new dynamic is needed in the production control at the factory having been created two laboratories.

2003 - 2004

Pavilion 4

Expansion of the manufacturing area for the production of large pipes and pre-slabs.

Pavilion 5

Production of highway concrete New Jersey barriers (k-rail) type.

2001

Certification of Quality and Environment

Development of quality products and sustainably has always been a primary objective in the ACL. Proof of this is the quality certification according to NP EN ISO 9001. We produce protecting! Our products are environmentally friendly, natural stone, water and Portland cement. 100% recyclable and all waste is reused.This makes us the first company in the sector to achieve the environmental protection certification according to norm NP EN ISO 14001.

Pavilion 3

Increased manufacturing area to produce stone flooring, junction boxes for sanitation and curb stone beams.

2000 - 2004

Football Stadiums

Providing material of construction for several stadiums, such as Stadium of Bessa, Stadium of Dragão (F:C.Porto), Municipal Stadium of Braga, Stadium Dom Afonso Henriques (Guimarães),Municipal Stadium of Aveiro, City Stadium of Barcelos, among others.

Railway line Renovation

Materials such as the Marmocim flooring, platform curb stones, walls, conduits and slabs contributed to this renewal of the railway line.

2000

1st International Exhibition (Construmat - Barcelona)

Export beginning

Following the participation in the Exhibition Construmat Barcelona and prepared for the efficiency of this global world, the jump for export took place at the beginning of the new century.

1996

Registration Marmocim Flooring

At the vanguard of his time, Marmocim stands out for being a high durability flooring with high abrasion resistance, also offering a huge variety of colors, textures and finishing.

1992

1st National Exhibition (FIL - Lisboa)

Participation in the International Exhibition of Construction and Public Works - FIL helped in the divulgation of the various products manufactured.

1991

Opening of Production Center Lousado (Factory 2)

There are new projects and new customers, resulting in a need to expand our infrastructure to a new production center, Production Center of Lousado. We believe!

1987

1st Automatic Machine

Acquisition of 1st automatic machine for the production of blocks with curing ovens.

1982

1st Machine Semi-automatic

Acquisition of 1st semi-automatic machine for the production of blocks.

1975

Foundation

Since origin (Louro) ACL has the values of excellence, innovation and commitment to do more and better in order to contribute to the evolution of its customers. We pursue quality in everything we produce!

Production Center Louro (Factory 1)

Production of blocks, pipes, rings, among others.